Analysis of the types of special spring manufacturers

Date of release:2020-10-29 00:00:00 Author: Click:

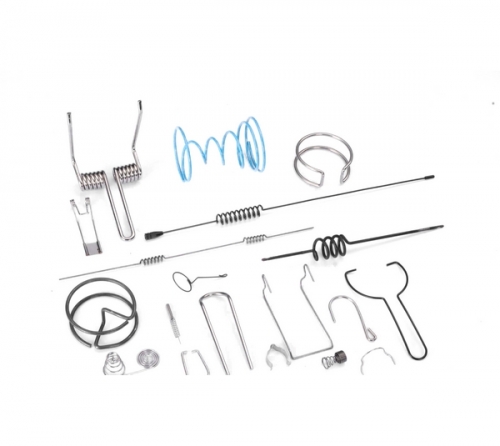

Variable diameter spiral shaped spring manufacturers: it is used for some special occasions, the diameter of the spring material is generally circular section material, and most bear compression load.

Sheet shaped spring: the material of this spring is spring strip (or plate), in special equipment or general pressure machining machine, through the corresponding mold processing. The material thickness of sheet spring, waveform spring, light spring is thinner, and medium or large special-shaped spring manufacturer's material thickness is often thicker, the use of this kind of special-shaped spring manufacturer is also very wide.

When the installation space is limited, the rectangular section of the material is often used in the special spring manufacturers, because the rectangular section of the material can be made of spring in the same space and the same amount of deformation under the larger load. This type of spring has a larger cross-sectional area in the same space than a spring of circular cross-sectional material, and therefore it absorbs more energy. It can be used in heavy machinery, stamping dies or springs with particularly high stiffness.

The dish-shaped spring is small in size and light in weight. It is used for buffering, vibration absorbing and other occasions. It is widely used in stamping die, valve clutch fasteners and petroleum and geological engineering machinery. Guangzhou special spring manufacturers custom _ custom processing

Analysis on the causes of abnormal hardness of steel reeds made by special-shaped spring manufacturers.

1, brittleness is one of the common defects of special spring manufacturers, can be divided into heat treatment brittleness and hydrogen embrittlement after galvanized 2 kinds. The fracture surface of hydrogen embrittlement was found to have crystal edge, dimple, secondary crack, etc. The hairline and hydrogen micropore were also observed on the segment crack.

2, heat treatment brittleness: shaped spring factory just has the thermal sensitivity and the temper brittleness tendency, while its HuoWen squarely in the first kind of temper brittleness and the second category of temper brittleness junction, if not timely tempering, heat preservation and cooling, will make the reed produces brittle junction, if not timely tempering, heat preservation and cooling, will make the shaped spring manufacturer produces brittleness.

3, hydrogen embrittlement

Hot dip galvanizing is easy to lead to the increase of brittleness of the special spring manufacturers, this is because before galvanizing, must be pickled to remove the oxide skin, will lead to a part of hydrogen infiltration into the plating layer and collective metal, weaken the binding force between crystal atoms and generate internal stress, make the reed become brittle, namely "hydrogen embrittlement".

4. Heat treatment cracks

The heat treatment usually results in a small probability of reed crack defect, which is caused by improper heat treatment process, improper adjustment of tooling, and operator error. Improper heat treatment process means that the reed heating temperature is too high and the holding time is too long, which causes the austenite grain in reed structure to be coarsened, and the martensite needle is thicker after quenching, which leads to the increase of the stress and brittleness of reed, thus forming the heat treatment crack.

The address of this article:http://en.afthcn.com/news/715.html

Key word:tensilespringmanufacturer,torsionspringmanufacturer,shapedspringmanufacturer

Recently browse:

Related products:

Related news:

- The safety of torsional spring manufacturers is the most important

- Stress test method for special-shaped spring manufacturers

- Shaped spring manufacturers in the production of defects will appear

- How does the stretch spring manufacturer prevent corrosion

- How to better choose the cleaning agent for precision hardware

- Why does the stretch spring manufacturer test it?

- Operation specification for precision hardware processing

- Torsional spring manufacturers working principle

- Heterosexual spring manufacturer: What are the functions of springs?

- How to let stretch spring manufacturers get rid of cracks