Shaped spring manufacturers in the production of defects will appear

Date of release:2021-11-26 00:00:00 Author: Click:

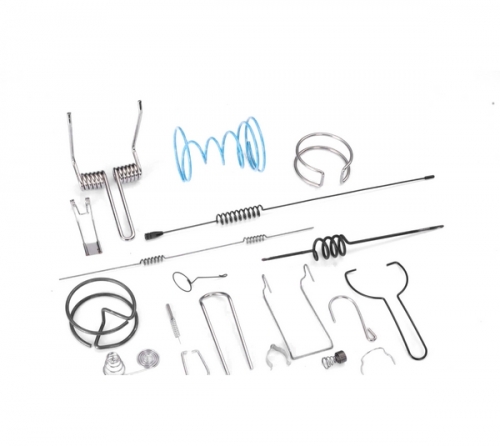

Shaped spring manufacturers are due to the process content is small, small curved buccal, the workpiece is particularly complex, but also need shape forming. Therefore, it is necessary to form die core and forming surface, and the forming condition of die structure is very big. The pressing area is very small.

The designer will consider the characteristics of the shaped spring, but ignore the shaped sliding stroke of the core, but this often has defects:

First of all, as the pressure core is a complex type, casting is used to process the guide surface after casting forming, resulting in clearance errors after the sliding of the machining surface and the guide surface of the concave surface. In the normal operation of the mold, the swing of the pressure core occurs from side to side.

2. The guide length of the compression core is designed to be 125 mm, and the actual guide length is 100 mm. Although within the design range, there was a 110 mm lift, the movement exceeded an effective guide length of 9 mm, and there was instability in the core-lift. The defect of inaccurate positioning of parts.

Thirdly, the forming height of the special-shaped spring is up to 100mm, which requires the design of a special guide slide, which cannot be guided by the gap between the working surface and the side wall of the die. The friction force of the slope is increased, and the self-lubrication effect is very poor, so the strong side force cannot be effectively eliminated. After mass production, the lead clearance will increase due to long-term wear, and the normal guiding effect of the die will be lost in advance, leading to a malignant quality accident

The address of this article:http://en.afthcn.com/news/718.html

Key word:tensilespringmanufacturer,torsionspringmanufacturer,shapedspringmanufacturer

Recently browse:

Related products:

Related news:

- The safety of torsional spring manufacturers is the most important

- How to better choose the cleaning agent for precision hardware

- How does the stretch spring manufacturer prevent corrosion

- How to let stretch spring manufacturers get rid of cracks

- Torsional spring manufacturers working principle

- Stress test method for special-shaped spring manufacturers

- Heterosexual spring manufacturer: What are the functions of springs?

- Why does the stretch spring manufacturer test it?

- Precision hardware can be cut according to production needs, and then some small accessories can be processed by Gong cutting or numerical control processing. Precision hardware containers must be processed with blanking punch, then welded, polished, spra

- Operation specification for precision hardware processing