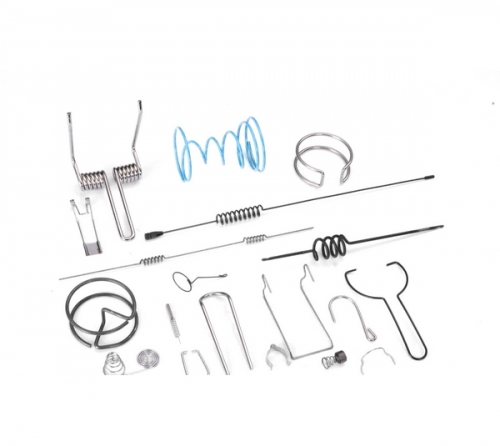

What should special spring manufacturers pay attention to?

Date of release:2020-08-25 00:00:00 Author: Click:

The abnormal spring determines the opening pressure, disc travel and sealing stability of the valve. If there is a problem with this spring, the whole valve will be difficult to work normally. On this basis, the causes of valve spring failure are summarized in order to pay attention to and prevent in the future operation.

The causes of frequent failure of valve spring are summarized as follows:

1. The load of high pressure spring can be divided into static load, impact load and vibration load according to the form of external force. The key reason of spring failure is high stress caused by large deformation and high load. High stress is only suitable for static load spring, low stress fatigue life is longer.

What should be paid attention to in the application of profiled spring?

2. The second step. Hydrogen embrittlement - if proper hydrogen solution is not carried out after electroplating or pickling, the spring will fail due to brittleness, but non-ferrous valve spring will not be affected. In electroplating solution, there is always a necessary amount of hydrogen ions in the electrolysis of water molecules. One part of the hydrogen ion causes hydrogen overflow, and the other part penetrates into the coating and metal body in the state of hydrogen atom, which reduces the toughness of the metal body and coating and becomes brittle, namely hydrogen embrittlement. Therefore, dehydrogenation should be carried out in oven or resistance furnace after electroplating or pickling. Temperature and time shall be determined according to spring size and coating thickness. The normal temperature should be between 150-250 ℃ and the holding time should be between 0.5-5 hours.

3. Severe bending and notch stretching, deformation and severe bending caused by leaf spring, grooving or scratch can cause high stress concentration and damage, so the bending radius should be as large as possible to prevent imprinting.

4. Fatigue - repeated deformation of springs, especially over 106 cycles, will cause fatigue damage even under moderate stress. When the operating conditions are bad, low stress should be selected to improve the fatigue of spring. Under the condition of reasonable selection of raw materials, shot peening can not only make the surface of spring smooth, but also improve the anti fatigue properties of spring and prolong the service life of spring. And can alleviate or even prevent surface decarburization, pits, indentation, cracks and other defects.

The address of this article:http://en.afthcn.com/news/666.html

Key word:tensilespringmanufacturer,torsionspringmanufacturer,shapedspringmanufacturer

Recently browse:

Related products:

Related news:

- Stress test method for special-shaped spring manufacturers

- Shaped spring manufacturers in the production of defects will appear

- How to better choose the cleaning agent for precision hardware

- Torsional spring manufacturers working principle

- Heterosexual spring manufacturer: What are the functions of springs?

- How does the stretch spring manufacturer prevent corrosion

- The safety of torsional spring manufacturers is the most important

- Why does the stretch spring manufacturer test it?

- Operation specification for precision hardware processing

- How to let stretch spring manufacturers get rid of cracks