Dispensing Spring

Taxonomy:Compression Spring

- Click times:

- Date of release:2020/07/07 15:19:24

- inquiry

- introduce

type | Compression Spring |

Wire gauge | 0.1~10mm |

Material | carbon steel,alloy spring steel,music wire steel,and stainless steel,iron,plated steel,alloy steel,bronze,red bronze,phosphor copper,and beryllium copper;etc |

surface treament | black oxide,Zinc/Nicke/Chrome plating,power coating,oiled to prevent rust,passivate,etc. |

GRINDING

Compression spring ends often are ground to increase operational life and to allow the spring to sit squarely on the load-bearing surface. Grinding also increases the number of active coils and the wire diameter available in a given volume of space, which can result in higher loads or lower stresses. As a modern compression springs manufacturer, our facilities operate with a wide variety of equipment - from hand-operated grinding tools to automatic, high-speed vertical spindle disc grinders.

DESIGN

Manufacturing tolerance requirements, squareness of ends, deflection and the slenderness ratio often are overlooked in the design process. Newcomb's sales and engineering staff will gladly review your compression spring specifications. We can offer design assistance and recommend the best options to control costs and make sure the spring functions to fit your needs.

The compression springs are an open coiled type, used where a load or force is required when compressed, or to store energy in the compressed position. A compression spring offers resistance to compressive forces. The rings are wound around, and both ends can be open or closed or flattened or flatten due to the pressure. The shape of the waist and even the various tails can be deformed by design. It is one of the most widely used of all kinds of springs.

Typical applications for compression springs include:

Aerospace

Valve

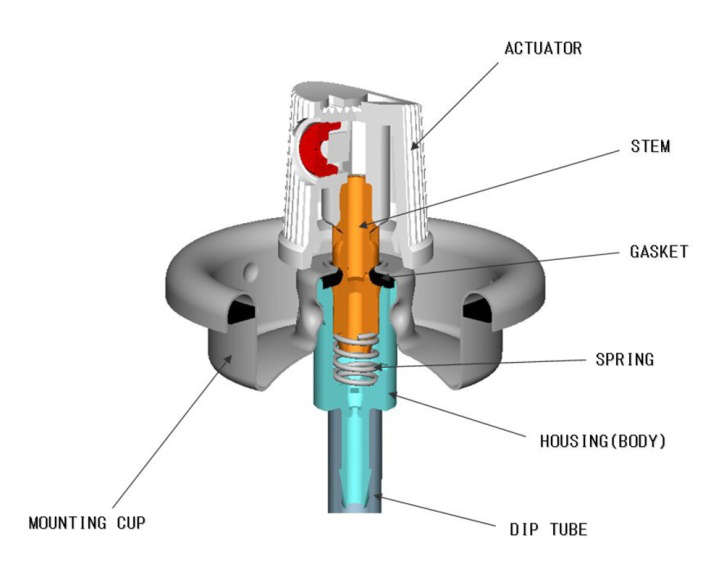

Spray

Off-road equipment

Automotive

Switches

Fluid/air control

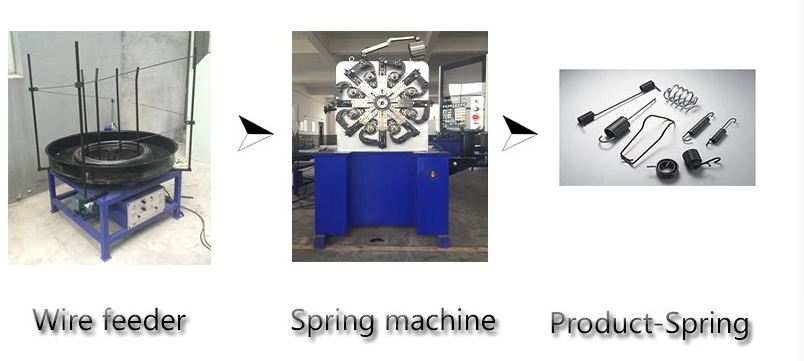

Our compression springs are made by advanced automation machine with high temperature to strengthen and finalize the shape, which has high accuracy and good stability.

Compression Springs

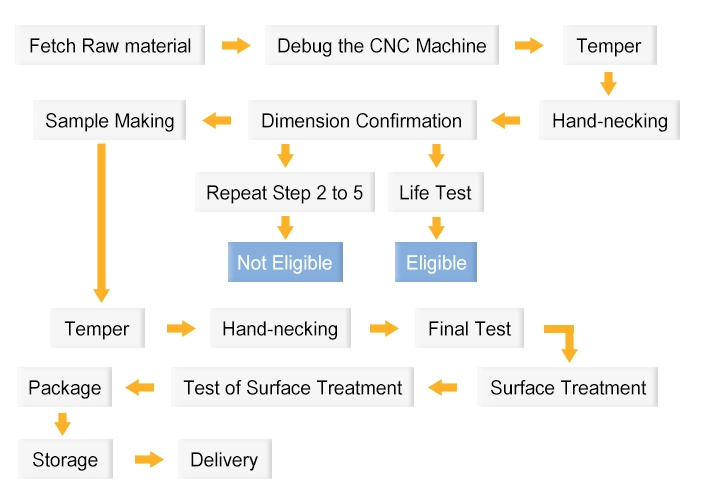

Production Process

Foshan Shunde Aofeng Spring Co.,Ltd. was established in 2004. In 2017, we set up another factory in Thailand. It located in the pearl river delta, which is beautiful, rich, economically developed and convenient for transportation. The firm is owned by the corporation, which is owned by springs, appliances, imprinting, canisters, etc. It is a research and development, design, manufacture and sales of precision spring and metal stamping products.

The company has gained a good reputation in the industry through a series of international professional certifications such as 1509001 and IATF16949.

Foshan Shunde Aofeng Spring Headquarter:

Thailand Aofeng Spring Branch: