How to improve the quality of spring manufacturers?

Date of release:2020-08-06 00:00:00 Author: Click:

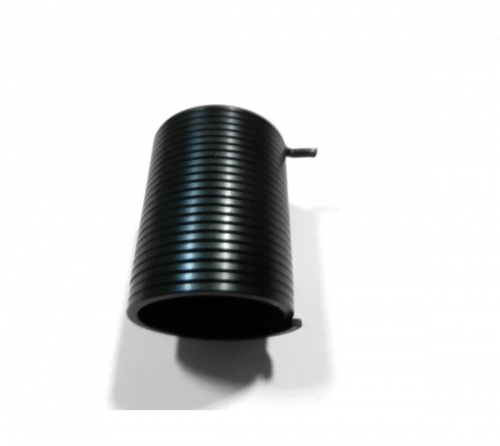

Stretch spring manufacturers are now the production and life of the necessary items, now there are many enterprises take a fancy to the market, vigorously produce, I believe that many people will ask about the special shape of the quality of stretch spring manufacturers how to improve? In fact, the factors that affect the output of spring manufacturers can be roughly divided into: drawing process, production organization and equipment reasons, the following are respectively introduced for you.

1, how to optimize the drawing process, the equipment number of drum under certain conditions, to keep the total compression rate unchanged at this moment, the decrease of the appropriate part of the compression ratio, appropriate to increase the number drawing, especially reduce the last part 1 original compression ratio, may change the state of the stress distribution inside the wire, the tensile strength reduced constantly, plasticity index rising, product qualified rate will be greatly improved.

2, in the process of drawing, stretching the spring manufacturer of sliding friction between steel wire and wire drawing die, could lead to uneven deformation of wire in the die hole, and will produce large amounts of heat energy, increase energy consumption amount, then you need to use wire drawing powder to dry and good liquidity, at the same time also need to often in drawing a stirring, to prevent wire drawing powder coking. Make sure the cooling channel of the die box and reel is smooth during the drawing process to maintain sufficient flow rate and keep the die box dry and clean. The wire drawing machine drum USES internal narrow slit water cooling and external forced air cooling. The finished drum USES internal spray water cooling and external annular gap forced air cooling. The hardness is relatively low, the water pressure is 0.2-0.3MPa, and the temperature should not exceed 30℃.

3, in the process of tensile spring manufacturers need to strictly control the "three a speed" wen, lead is to control the temperature, temperature, wire line temperature, running speed in the furnace, so can reduce the oxidation of steel wire surface, prevents the steel wire hanging lead, at the same time to strengthen the administration of the lead tank can ensure that cover sealed lead liquid surface, can pan steel wire in the lead of crossover operation. In addition, it is also necessary to control the broken head, loose head, do not stop off the line.

The address of this article:http://en.afthcn.com/news/652.html

Key word:tensilespringmanufacturer,torsionaspringmanufacturer,,shapedspringmanufacturer

Recently browse:

Related products:

Related news:

- The role of hot coil spring is not to be underestimated

- Heterosexual spring manufacturer: What are the functions of springs?

- The safety of torsional spring manufacturers is the most important

- Torsional spring manufacturers working principle

- Stress test method for special-shaped spring manufacturers

- What are the factors that affect the selection of spring material?

- How to let stretch spring manufacturers get rid of cracks

- Shaped spring manufacturers in the production of defects will appear

- Why does the stretch spring manufacturer test it?

- Processing characteristics of spring zinc plating