How to improve the service life of spring?

Date of release:2020-03-27 00:00:00 Author: Click:

To increase the service life of the spring, some of the following treatments need to be done during production.

Spring isothermal quenching: for smaller diameter or hardenability enough spring can be used isothermal quenching, it can not only reduce the change of heart, but also can improve the strength and toughness. After isothermal quenching, try again to temper, can improve the elastic limit, tempering temperature and isothermal quenching temperature is the same.

Spring relaxation processing: spring for a long time under the action of the external force, due to stress relaxation, will produce a trace of long-term (plastic) deformation, especially high temperature work of the spring, stress relaxation under high temperature is more serious, make the spring precision, which is not allowed to general precision spring. Therefore, this kind of spring in quenching, tempering should be relaxed treatment. Heat treatment process: load the spring in advance to make its deformation more than the spring may produce deformation. Then it is heated at 20℃ higher than the working temperature for 8~24h.

Deformational heat treatment: deformational heat treatment is the combination of steel deformation strengthening and heat treatment strengthening to further improve the strength and toughness of steel. Deformation heat treatment can be divided into high temperature, moderate temperature and low temperature. High temperature deformation treatment is produced in a stable austenitic state immediately after quenching, can also be combined with forging or hot rolling, that is, immediately after hot forming quenching. After high temperature deformation treatment (930℃+ thermal variable 18%, oil quenching), the automobile plate spring made of 60Si2Mn steel is quickly tempered at 650℃×3.25min, and its strength and fatigue life are greatly improved.

Shot peening: shot peening is one of the most widely used methods to improve spring surface quality. Spring requires a high surface quality, scratches, folding, oxidation and decarbonization and other surface defects tend to become the spring when working stress concentration and fatigue fracture source. If a small steel shot is sprayed on the surface of the spring at high speed, it can not only improve the surface quality of the spring, improve the surface strength and make the surface in the state of compressive stress, so as to improve the fatigue strength and service life of the spring.

The address of this article:http://en.afthcn.com/news/615.html

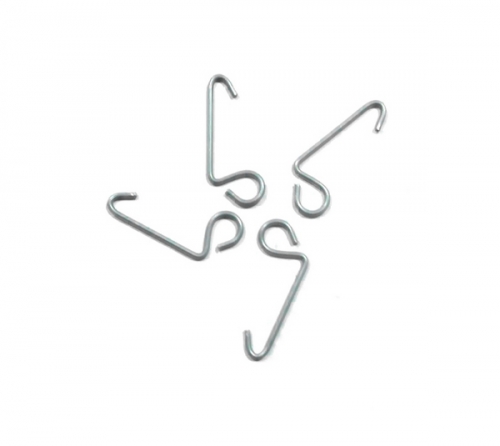

Key word:拉伸弹簧厂家,扭转弹簧厂家,异形弹簧厂家

Recently browse:

Related products:

Related news:

- What are the types of springs?

- What are the properties of a plane coil spring?

- Look at the compact function of hardware springs

- The role of hot coil spring is not to be underestimated

- Frequently asked questions about stretch springs

- Heat treatment process of shaped spring

- Processing characteristics of spring zinc plating

- How to pressure test precision spring?

- How to choose medical instrument spring

- What are the factors that affect the selection of spring material?